Products

Automotive Diagnostics Products

BSE develops and manufacturers handheld diagnostic tools for the automotive industry. With our partner companies, we provide a full compliment of tools to support content development within OEM engineering, manufacturing, and service organizations. Diagnostic tools are built to the specific customer requirements and are used for servicing vehicles in dealerships and manufacturing plants throughout the world.

smartEdge Telematics Platform

Bright Star Engineering’s smartEdge Telematics Platform is a comprehensive hardware and software suite that includes:

- User Customizable Dashboards

- Trend Analysis and Prediction

- Vehicle Diagnostics Engine

- Fleet Tracking Dashboard

- GUI and Script Based Rules Engine

- Advance Role-Based Access Control

- SIM & Cellular Management

This powerful suite is capable of data collection, processing and visualization, and data analytics and prediction. With included GPS functionality, the platform allows fleet tracking features such as mapped route tracking, alarm panels, historical playback, and more.

Our GUI and script based rules engine allows users to quickly and easily define data processing rule chains, aggregate and route data, trigger scripts, and schedule ECU updates.

Mopar Diagnostic Pod

The Mopar Diagnostic Pod (MDP) for wiTECH 2.0 and wiADVISOR provides advancements required to diagnose and repair newer Stellantis vehicles including the 2021 WL that are equipped with the Atlantis High vehicle architecture. The Atlantis High architecture incorporates new vehicle communication technology including CAN FD and Ethernet which are not supported on the microPOD II device.

MDP key benefits:

- Small size (approx. 2.9” x 2.2” x 1.3”)

- Supports new CAN FD and Ethernet vehicle communication technology

- Required for future Stellantis vehicle programs beginning with the 2021 WL

- Supports all vehicles supported by microPOD II

- Increased speed and performance

- Increased memory and storage space

- Improved Wi-Fi with support for 2.4GHz & 5GHz, 802.11 a/b/g/n/ac

- Includes “Mopar Blue” protective boot

Honda Antares Capsule

The Honda Antares Capsule is a variant of our wireless Antares diagnostic interface that supports Honda and Acura vehicles from 1996 model year to current. Plug it in and go — Get up and running faster than ever before!

- Wi-Fi Connectivity

- Ultra-compact size

- 5 second boot up time!

- Rugged protective rubber boot

- Waterproof protective storage case

- Full support of HDS and i-HDS

- Full support of Honda ECU Reprogramming

- Smart VCI Functionality

- Made in USA!

microPOD II

Bright Star Engineering’s microPOD II is equipped to act as a vehicle network gateway for pass-thru diagnostic applications or can operate standalone for monitoring/logging applications. The internal 450 MHz ARM CPU and Linux OS provide a powerful platform for pass-thru diagnostic, monitoring and telematics applications. The internal 2+ GByte flash disk provides ample local storage for user applications and recorded vehicle data. The microPOD II also provides a sleep mode whereby it turns off, drawing only 750 uA of current and will wakeup upon detecting bias or traffic on the CAN bus. The microPOD II also incorporates a rich software environment including wireless network management/security, pass-thru diagnostic protocol services, data recording services, web configuration GUI, Java JVM as well as system features for in the field software upgrades.

The microPOD II is small enough to fit in a shirt pocket and offers 100-percent CAN coverage for Chrysler, Dodge, Jeep and Fiat vehicle platforms. This dongle-style, PC-based device can be used in place of the StarMobile, StarScan and wiTECH Pod scan tools and is smaller, faster, and half the cost of its predecessor. The diagnostic time savings is large due to the superior organization and logical navigation of web based wiTECH software.

J2534 Device

BSE’s J2534 device is a compact design with an integrated vehicle cable. It supports all OBD protocols and has 4 CAN BUS channels that can be used simultaneously. The device also includes legacy Chrysler SCI and CCD protocols and is certified by Chrysler for use on all on all Chrysler/Jeep/Dodge vehicles.

- Connects to Windows PC using USB Cable

- 400 MHz 32-Bit ARM CPU

- Industrial Temperature Range

- Allows the user to flash ECUs with the use of OEM software

- Full One Year warranty

wiTECH 2.0

wiTECH 2.0 introduced the first web-based OEM diagnostic tool in the industry. This included a microPOD device that could be reached remotely through a cloud server using tablets, smartphones, and PCs. wiTECH 2.0 architecture allows each user to enhance their diagnostic speed, range, and mobility.

Benefits include:

- Ability to diagnose vehicles anywhere thru Internet

- microPod device is smaller, faster and half the cost of its predecessor

- Saves technician diagnosis time and effort

- Securely share vehicle diagnostic information with help desks and technical advisors

- Global ready tool offers cost effective development and support for global enterprise

wiADVISOR

The wiADVISOR platform uses BSE’s micropod device to assist service advisors in providing accurate, consistent and transparent service write-up experiences to their customers. The system arms service advisors with required information at their fingertips and eliminates the need to search through various systems and databases. WiADVISOR even determines if all the vehicle computers are running the current level of software. With access, service advisors may immediately print out factory-required and dealer-recommended maintenance requirements tailored specifically for that customer’s vehicle.

Manufacturing Diagnostic Tools

To support manufacturing and further extend the diagnostic process chain, the service and engineering diagnostic hardware and software was extended and optimized for the manufacturing environment. When electrical issues occur on a vehicle while being processed on the assembly line, the vehicle is moved to a repair bay where the manufacturing tool is used to assist with diagnostic troubleshooting.

Engineering Diagnostic Tools

BSE engineers worked with OEM engineering organizations to introduce a more comprehensive diagnostic and flash application that leveraged the service tool hardware. These tools allow internal engineering OEM organizations to test ECU diagnostic support and perform flash updates when changes are required, and marked the introduction of a unified process chain for both engineering and service diagnostic tools. This process chain includes applications and utilities that manage input source data, collaboration between engineering organizations, and content sharing and promotion.

wiTECH

wiTECH delivered the industry’s first interactive topology that enabled technicians to view vehicle specific information. wiTECH introduced a legacy tool emulator that allows previously launched tools and software to continue to be used without the full cost of migrating to the new platform. wiTECH also introduced a single global diagnostic application, which was faster and nearly half the cost of its predecessor.

Benefits include:

- Smaller package at lower cost

- Improved technician comprehension of increasingly complex vehicle architectures

- Global ready, multi-vehicle, multi-language tool

- Became the standard for other tools, allowing all OEMs to improve the diagnostic process

StarMOBILE

StarMOBILE came to market as the first WiFi PC based scan tool with flight recorder capability that captures diagnostic information while the customer drives the vehicle.

Benefits include:

- Increased diagnostic response time resulting in 50% reduction in dealership diagnostic costs

- Introduction of the flight recorder feature improved diagnosis of vehicles with intermittent issues

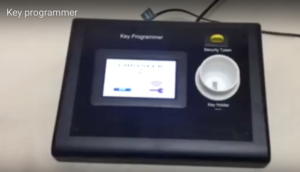

Key Programmer

The Key Programmer tool is used to program automotive keys with an immobilizer feature. The tool has the following features:

- 4.3″ LCD with touchscreen

- Linux operating system

- GTK+ X11 user interface

- Connectors: Power, Ethernet, and USB

StarSCAN

StarSCAN introduced the first color touch screen diagnostic tool. Other features include an industry first vehicle topology screen, CAN support, and direct connection to the network.

Benefits include:

- Provided improved vehicle diagnostic process and higher quality of diagnostic data

- The network topology view developed in partnership with the OEM is now used by many other OEMs today

- Improved speed and access to the vehicle diagnostic knowledge base

Daimler Chrysler Diagnostic Interface

Custom Electronic Control Products

FAA Radar Installation & Beacon Control Board

BSE has developed radar installation and beacon control boards used in US Federal Aviation Administration (FAA) radar installation and beacon sites. The FAA is primarily responsible for the advancement, safety, and regulation of civil aviation and BSE is proud to assist the FAA in their continuing mission to provide the safest, most efficient aerospace system in the world.

WorldSID Crash Test Dummy Control Board

A network of five of BSE nanoEngines are used inside each WorldSID crash dummy as part of the in-dummy data acquisition system that captures up to 200 channels of sensor data during the crash event. Robust BSE electronics readily meet the requirements of this harsh environment where control boards need to withstand shocks of up to 500 G’s and operate at temperature extremes of 70 degrees centigrade.

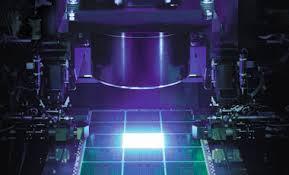

Semiconductor Photolithography System Control Board

BSE has expertise in developing control boards for controlling laser illumination sources for photolithography systems used in the manufacturing of semiconductors. One of our customers, Cymer LLC, has used our product as part of their semiconductor fabrication processes worldwide.

Test System Products

Smart Breakout Box

The Bright Star Engineering Smart Breakout Box (SBoB) performs in-circuit testing of cable harnesses to locate cable, component, sensor, and actuator faults. The SBoB utilizes analog signature impedance analysis to compare the analog signatures of each circuit within the harness against a database of known good signatures. This analysis can be done on a vehicle in the repair bay without requiring extensive vehicle disassembly. The ECU breakout adapter is simply attached between the ECU and harness with the SBoB attaching to the adapter.

Smart Cables

Our expertise in developing network-enabled circuit boards is a natural fit for designing smart cables that need a measure of electronic control included in the harness. In many cases, preexisting hardware can be extended to add additional features or support at a fraction of the cost of replacing the entire design. Our quick prototype team can provide the answer in a cost-effective manner.

Automated Regression Testing Racks

Release management and validation testing are critical components to the success of any large-scale development where content is delivered over time in a progressive fashion. Automated testing through one of our regression testers allows for regression testing of all previously delivered content as new content is added.

For an example of our automated test systems, see the Anvil Automated Testing System case study below.

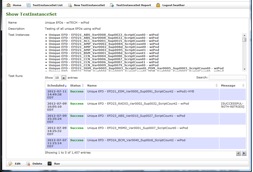

Case Study: Anvil Automated Testing System

In many applications, thousands of changes are introduced to the software and content that could affect previously released support. Development organizations without regression testing are faced with expensive manual revalidation or worse yet, forced to leave it to the end-customer to call if new releases break previously released functionality and content. The former leads to high retesting and revalidation costs, the latter leads to poor quality, lost productivity, and low customer satisfaction.

In partnership with a major automotive OEM, BSE developed a regression testing system called Anvil to keep revalidation costs low while maintaining quality, productivity, & customer satisfaction targets. The system regression tests previously released vehicle content to assure new releases of content doesn’t break previously released support.

In partnership with a major automotive OEM, BSE developed a regression testing system called Anvil to keep revalidation costs low while maintaining quality, productivity, & customer satisfaction targets. The system regression tests previously released vehicle content to assure new releases of content doesn’t break previously released support.

The results? In a recent year of development, 111,412 changes were introduced in 20 software and content releases. Anvil successfully regression tested the software packages to assure those changes did not unintentionally break previously released content and support. The system was able to do this by running 1090 validation tasks and 55,432 tests that take between 15 minutes and 8 hours to perform. Running those tests with manual labor would have been cost prohibitive, but Anvil was able to automatically perform its testing duties tirelessly around the clock at a fraction of the time and cost.

Standalone Single Board Computer Products

The cost of enabling products for the Internet can be prohibitive in time-to-market delays as well as startup and long-term maintenance costs. Bright Star Engineering’s family of single board computers significantly reduce the time, cost, and complexity required to network enable a product. BSE provides the required hardware, software, and development environments needed so you can concentrate on other execution details of you project with confidence.

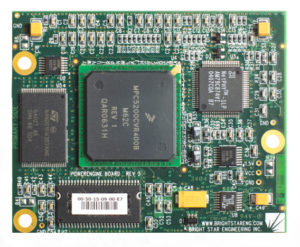

p2Engine

The p2Engine is a versatile, low-cost, high-power computing platform. The p2Engine consists of a microprocessor, SDRAM, NOR Flash, NAND Flash, an Ethernet PHY, USB and EIA/TIA 232 transceivers. Running at 398 MHz, the PPC core performs just under 760 MIPS.

Design Goals:

- Versatile

- Industrial temperature range

- Common core

- Low-cost

- High reliability

- Smaller than a credit card! (2.9″ x 2.35″)

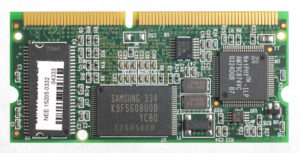

picoEngine

The picoEngine provides base control for a small handheld electronic device. A bootloader is used to initialize the PicoEngine and load the primary operating system from flash memory, from the network or from the serial console. The PicoEngine can be readily used with a variety of operating systems including Linux and Windows.

The PicoEngine has the following significant features:

- AMD Au1100 400 MHz MIPS32 CPU

- 64 MB SDRAM

- 8 MB Boot Flash

- 32 MB NAND Flash (solid state disk)

- 10/100 Ethernet

- Three RS-232

- LCD Controller

- AC’97 Audio Codec Interface

- Real-Time Clock

- Dual USB Host

- Smaller than a business card! (2.5″ x 1.25″)

ipEngine

The ipEngine utilizes Motorola’s PowerPC MPC823 processor with an array of on-chip peripherals including Ethernet, USB, LCD/Video, I2C and serial controllers. The on-board flash memory file system provides storage for the operating system as well as OEM application software and data. By employing POSIX and ANSI C standards, the ipEngine’s software environment leverages a familiar programming environment and facilitates migration of software from UNIX and Windows platforms.

The external interface to the ipEngine hardware is via an FPGA-based 88 pin virtual interface that can be configured on the fly to adapt to the OEM’s needs. The FPGA can be configured to emulate a variety of bus architectures as well as to implement peripheral functions like UARTs, PWM control, memory emulation, data capture and synthesis, and interfaces to a variety of input devices.

- 50 MHz MPC823 CPU

- 16 MB DRAM

- 4 MB FLASH

- 10Base-T Ethernet

- On-Board 16 Watt Power Supply

- 16,000 Gate FPGA

- 132 Pin Virtual I/O Interface

- USB Host/Slave Controller

- LCD/Video Controller

- Dual RS-232

nanoEngine

Bright Star Engineering’s nanoEngine single board computer provides an unprecedented level of power and integration in a 1.4″ by 2.4″ module. Utilizing the Intel SA1110 StrongARM processor, the nanoEngine is able to provide desktop system class-performance yet consumes well under 2 watts of power. In conjunction with the 200 MHz processor core, the nanoEngine’s on-board 10/100 Ethernet controller is able to provide in excess of 80 MBits/sec sustained user-level TCP performance.

BSE’s nanoEngine provides customers with a choice of external interfaces. In one mode the external interface is configured as a PCI bus interface including a PCI bus arbiter and interrupt controller. This allows seamless connection to common PCI peripheral components. The external interface can also be placed in a generic bus mode allowing direct connection to common memory and peripheral devices.

- 200 MHz StrongARM CPU

- 8-64 MB SDRAM @ 100 MHz

- 1-16 MB FLASH

- 10/100 Ethernet

- 3 RS-232 Ports

- LCD Controller

- Generic User Bus Interface

- Smaller than a business card! (1.4″ x 2.4″)

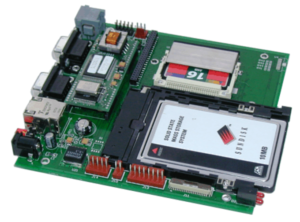

Legacy mediaEngine Board

The Legacy mediaEngine support legacy interfaces used in older hardware designs including compact flash and PCMCIA cards. The board supports the following:

- 133 or 200 MHz StrongARM CPU

- 8-64 MB SDRAM @ 100 MHz

- 1-20 MB FLASH

- Type II Compact Flash Socket

- Type I/II/II PCMCIA Socket

- 10 Base-T Ethernet

- 2 RS-232/RS-485 Ports

- 1 RS-232 Port

- Battery Backed Real-Time Clock

- Expansion Header (for add-on I/O cards)

- Internal V.90 Modem

- LCD Panel Controller

- USB Slave Interface